When designing our machines, we aim to create:

- Compact equipmen

- Optimum mechanical reliability

- Maximum performance with variable flow rates

- Guaranteed operation with the full range of turbine flows

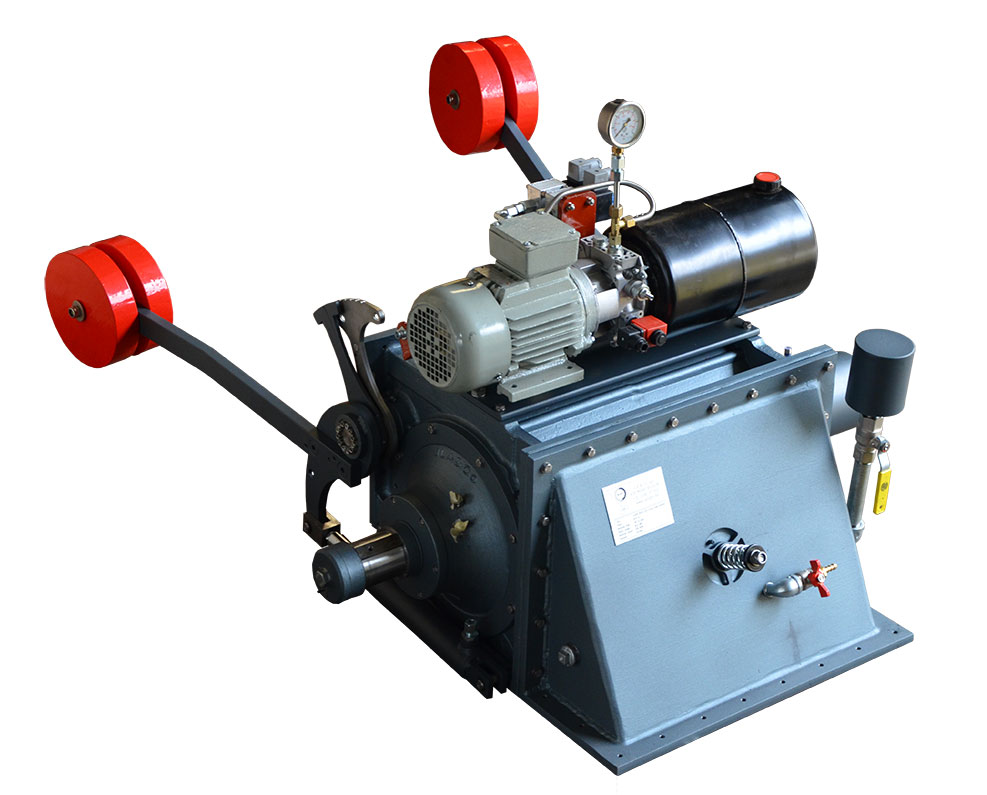

The turbine casing is made of cast iron, which has the following advantages:

- Excellent castability and easy machining which reduces costs

- Excellent corrosion resistance

- Dimensional stability

The bearings, which are also made in cast iron, are:

- Specially made for our turbines

- Equipped with a double-ring sealing system with central lubrication, which ensures that the turbine casing remains watertight

- Protected against any inflow of water

All the turbine components are easily accessible, which greatly facilitates the removal of any part (runner, roller bearings, etc). Maintenance is limited to occasional lubrication of the bearings and seal rings. The runner can easily be checked by removing the turbine cap.

As the turbine casing is watertight, it is possible to use the full drop height by controlling the depression under the turbine runner.

Depending on the configuration of the site, the water inlet can be either vertical or horizontal.

The flow rate is controlled by means of a low operating torque using one or two specially profiled valves, fitted with a stainless steel axle and watertight. These valves split the water flow in two, before shaping it so that it penetrates the runner without shocks.

The flow rate control devices are easy to regulate – either by using electric/hydraulic actuators or manually.

The runner consists of laminated steel blades, which are hydraulically designed and specially profiled in order to optimise turbine efficiency.

These blades are mounted between two flanges and carefully welded, using a special procedure developed at the JLA Hydro workshops. When the drop height increases, intermediate reinforcement disks are added in order to make the whole system rigid. The runner is then hot-dip galvanised and coated with epoxy, which makes it highly corrosion and abrasion resistant.

All our runners are dynamically balanced. They are symmetrical, so that the PTO can be located on the left, right or even on both sides, depending on the layout.

A JLA Cross-Flow is straightforward to install, costs very little and respects the environment. It is easy to control, to maintain and it is exceptionally long-lasting.

JLA Cross-Flow turbines are designed to be mounted on a metal frame above the outlet channel and as low as possible but out of reach of the floods.

In the event of a low head with a variable downstream level, the turbine is fitted with a draft tube so that the full available head can be used efficiently, regardless of the downstream level.